Nuclear Quality Systems

World-class Nuclear

Quality Systems

Having been developed for over three decades, NFT™’s Quality System encompasses NQA-1 Nuclear Quality Assurance and the associated Code of Federal Regulations requirements.

NFT’s divisions currently feature 17 separate training and qualification programs ensuring our more than 20 inspection and test personnel are qualified to correctly perform, report and interpret the tens of thousands of Non-Destructive examinations and tests our products and services undergo each year.

These highly qualified individuals, using many hundreds of calibrated devices and testing systems, make it possible for NFT to ensure the technically demanding products we produce are suitable for use in exacting environments with demanding personal and public safety requirements.

Certifications

NFT™ maintains multiple quality systems to address your manufacturing, production, and testing needs from Nuclear to Commercial. NFT also maintains compliance with multiple Code of Federal Regulations (CFR) and Department of Energy (DOE) requirements.

NQA-1 Quality System

NFT™ maintains an ASME NQA-1 Part 1 Complete Quality System which regulates all nuclear work. NFT’s main focus in the nuclear industry is on safety and containment of nuclear materials. Our products include filters, containers, transportation, maintenance, and analytical systems across the nuclear industry. Our facilities and records are permanently open to clients and government agencies, for auditing and inspection purposes, ensuring excellence in document control and record preservation.

Click here to view the current Procedure List.

Click here to view the current Quality Assurance Program Description (QAPD).

Click here to view the NFT Subcontractor Quality Clauses (NFT Vendor Flowdowns).

Nuclear Quality

Compliance Bases

American Society of Mechanical Engineers (ASME)/American National Standards Institute (ANSI) NQA-1, Quality Assurance Requirements for Nuclear Facility Applications, 2008 Edition, 2009 Addenda, and previous revisions (NQA-1).

ANSI COMPLIANCE

- Nl4.5-1997 Radioactive Materials – Leakage Tests on Packages for Shipment.

- N14.1-2001, Addendum 1 supplement to ANSI N14.1-2001 American National Standard for Nuclear Materials Uranium Hexafluoride – Packaging for Transport.

- Z540-1-1994, Calibration Laboratories and Measuring and Test Equipment-General Requirements.

SNT-TC-1A Certification for NDT Personnel 1980 – 2011

CODE OF FEDERAL REGULATIONS COMPLIANCE (CFR)

- 10 CFR 50: ”Domestic Licensing of Production and Utilization Facilities,” Appendix B, ”Quality Assurance Criteria for Nuclear Power Plants and Fuel Reprocessing Plants”

- 10 CFR 21 “Reporting of Defects and Noncompliance”

- 10 CFR 830.120

- 10 CFR 71, ”Packaging and Transportation of Radioactive Material, Subpart H, Quality Assurance”

- 49 CFR 173.475 “Quality control requirements prior to each shipment of Class 7 (radioactive) materials”

- 49 CFR 173.474 “Quality control for construction of packaging Class 7 (radioactive) material”

- 10 CFR 72, ”Licensing Requirements for the Independent Storage of Spent Nuclear Fuel, High Level Radioactive Waste, and Reactor-Related Greater Than Class C Waste, Subpart G, Quality Assurance.”

Regulatory Guide 1.28, 2010 “Quality Assurance Program Criteria” Design & Construction. (RG 1.28)

Regulatory Guide 7.10, Rev. 2 ”Establishing Quality Assurance Programs for Packaging Used in Transportation of Radioactive Material.” (RG 7.10)

Department Of Energy Letter 414.c. (DOE 414c)

Inspection & Testing

NFT offers various forms of inspection and testing including:

Visual

Dimensional

- Manual Inspection Equipment

- Fully Programmable DCC-CMM

- Optical Comparator

- Romer Arm up to 14’

Ultrasonic Thickness

Optical Inspection

Welding (Certified Welding Inspectors)

- Visual

- Dye Penetration

- Fluorescent Dye Penetration

- Magnetic Particle Testing

- Radiographic Testing

Filter Efficiency Testing

- Flow Rate & Resistance Testing

- Hydrogen Diffusion Coefficient Determination

Hydro/Pneumatic Testing

Leak Testing

- Helium Leak Rate by Mass Spectrometer

- Pressure Decay Leak Rate

- Bubble Leak Rate

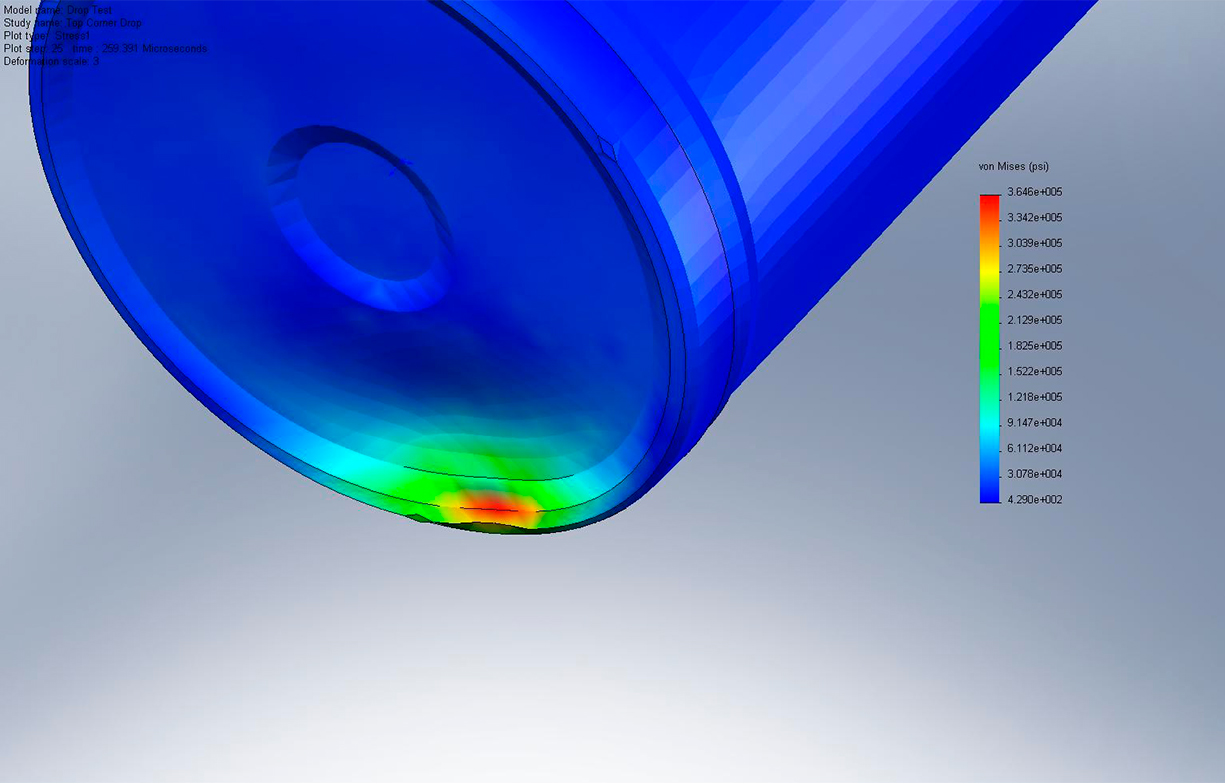

DOT 7A Drop Test

FEA Analysis